Ever wondered how frozen french fries are made? Dive into the high-tech world of frozen french fry processing lines. Discover the steps from potato to perfect fry, ensuring quality, safety, and taste.

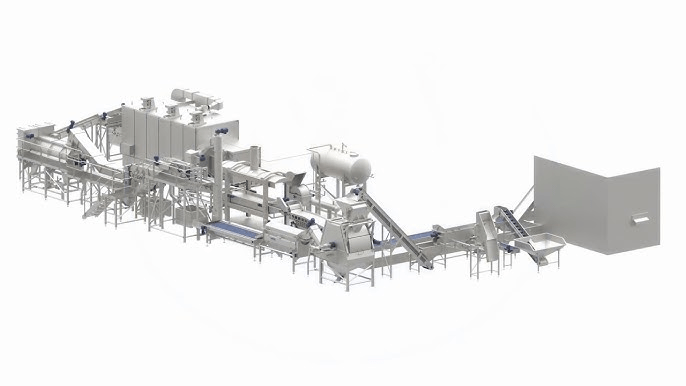

Our company designed a fully automatic quick-frozen French fries production line with high quality and high speed, using advanced Dutch technology. It can achieve 300-10000kg per hour.

The humble french fry is a global superstar. From fast-food chains to family dinners, its crispy exterior and fluffy interior are universally loved. But have you ever stopped to think about how these perfect fries make it from a raw potato in a field to a consistent, convenient product in your freezer?

The answer lies in a highly sophisticated and automated frozen french fry processing line. This marvel of food engineering ensures every batch meets strict standards for size, color, and texture. Let’s explore the key stages of this fascinating journey.

- Receiving and Sorting

The journey begins with the potato. Not just any potato will do. Specific varieties, like Russet Burbanks, are chosen for their high starch content and low sugar, which is ideal for frying. Upon arrival at the plant, potatoes are unloaded and undergo initial sorting to remove rocks, debris, and defective tubers. - Washing and Peeling

The sorted potatoes are then conveyed through high-pressure water jets to remove dirt. Next, they enter a peeler. Modern plants often use steam peeling or abrasive peeling, which efficiently removes the skin while minimizing waste and water usage. - Cutting and Trimming

This is where the potato becomes a fry! The peeled potatoes are propelled at high speed through a cutting head lined with sharp blades, slicing them into uniform strips—whether classic, shoestring, or crinkle-cut. Optical laser sorters then scan each strip, automatically ejecting any with blemishes, green spots, or incorrect size. - Blanching: The Critical Step.Blanching is a crucial thermal process. The cut fries are immersed in hot water for a specific time. This serves multiple Enzyme Inactivation: Prevents discoloration and off-flavors during storage. Sugar Removal: Leaches out excess sugars that would cause uneven, dark frying. Pre-cooking: Sets the structure, creating the desired fluffy interior.

- . Drying and Pre-Frying: After blanching, the fries are thoroughly dried using centrifugal force or air knives. Any surface moisture would cause violent oil splattering during the next step: par-frying (partial frying). The fries travel through a hot oil bath just long enough to cook the exterior, forming a thin crust that will become crispy upon final preparation. This step also develops the characteristic flavor and golden color.

- Flash Freezing (IQF): To lock in freshness and quality, the par-fried fries must be frozen rapidly. They enter an Individual Quick Freezing (IQF) tunnel, where they are blasted with extremely cold air. This rapid freezing prevents the formation of large ice crystals that can damage the potato’s cell structure, ensuring the fries don’t become mushy when cooked. The “IQF” means each fry is frozen separately, so they don’t clump together in the bag.

- Packaging and Palletizing: Finally, the frozen fries are weighed and packaged using automated systems into bags, cartons, or bulk packages for food service. Metal detectors and checkweighers ensure product safety and compliance. The packaged boxes are then automatically stacked onto pallets and moved to cold storage, ready for distribution.

Why a Modern Processing Line Matters

A state-of-the-art frozen french fry production line is not just about efficiency; it’s about delivering a superior product. It guarantees:

- Consistency: Every fry is nearly identical in size and quality.

- Food Safety: Automated, hygienic processes minimize human contact and contamination risks.

- Nutrition & Tastefreezing preserves the taste, texture, and nutritional value of the potato.

The next time you enjoy a portion of crispy french fries, remember the incredible technology and precision that went into making them. The frozen french fry processing line is a perfect example of how food technology delivers convenience without compromising .

留下评论