Thermoforming Vacuum Packaging: The Ultimate Guide to Industrial-Grade Freshness & Efficiency.

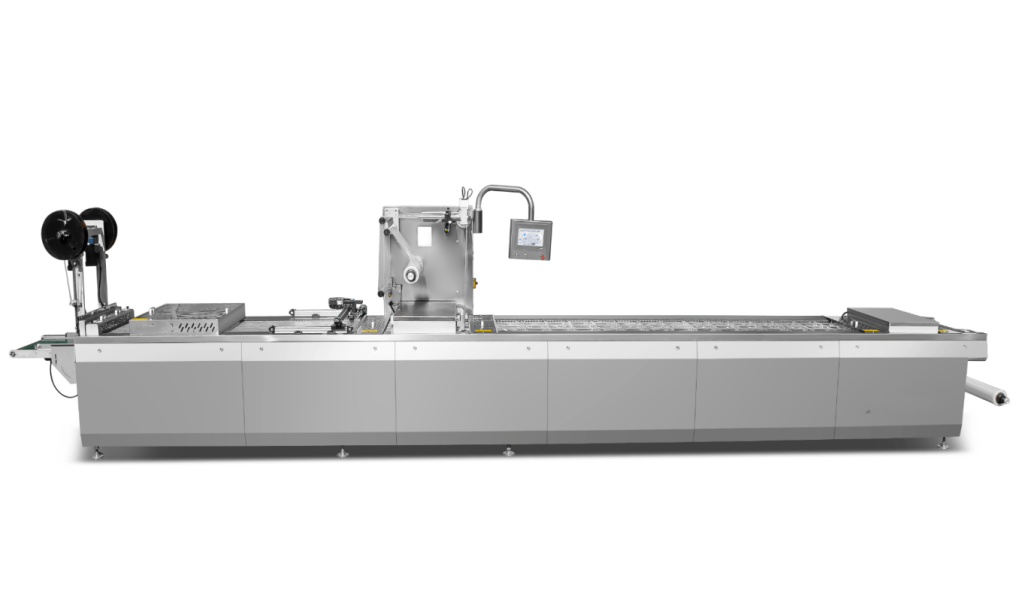

Discover how the thermoforming vacuum packaging machine revolutionizes food preservation, extending shelf life and increasing production efficiency. This advanced machine, built with advanced German technology, can meet your production needs.

In the competitive world of food production and manufacturing, presentation, preservation, and efficiency are non-negotiable. While standard vacuum sealers get the job done for small-scale operations, businesses looking to scale up need a superior solution. Enter the thermoforming vacuum packaging machine – the powerhouse of industrial packaging.

But what exactly is it, and why is it a game-changer for so many companies? Let’s dive in.

What is a Thermoforming Vacuum Packaging Machine?

In simple terms, a thermoforming vacuum packager is an automated system that creates a package from a roll of plastic film, precisely molded around your product.

Here’s how it works in three steps:

- Thermoforming:The lower film is heated and pneumatically drawn down into a mold, creating perfect cavities or trays tailored to your product’s shape.

- Loading:The product is placed into the newly formed pockets. This can be done manually for artisanal goods or automatically with robotic systems for high-volume lines.

- Vacuum Sealing: The upper film (the lidding material) is placed over the filled cavities. The machine then evacuates all the air, creates a modified atmosphere (MAP) if required, and heat-seals the package shut.

The result? A robust, custom-fit package that looks professional and offers unparalleled protection.

Key Advantages Over Traditional Vacuum Packaging

Why should your business consider upgrading to a thermoforming system?

- Unbeatable Product Presentation: The custom-formed tray showcases your product beautifully, enhancing its appeal on the shelf. This is ideal for meats, cheeses, prepared meals, and medical devices.

- Superior Shelf Life Extension: By removing oxygen more effectively than bag-based systems, thermoforming drastically slows down oxidation and spoilage. When combined with Modified Atmosphere Packaging (MAP), it can extend freshness by weeks or even months.

- Remarkable Efficiency & Speed: These machines are built for volume. They can produce hundreds of perfectly sealed packages per hour, significantly outpacing manual methods and reducing labor costs.

- Reduced Material Waste & Cost: Using roll stock film is often more cost-effective than pre-made pouches or trays. You only use the exact amount of material needed for each product.

- Exceptional Durability:The formed trays are strong and resistant to punctures, ensuring your product is protected throughout the supply chain.

Is a Thermoforming Machine Right for Your Business?

This technology is ideal for:

- Food Producers: Especially for fresh meat, dates, poultry, fish, cheese, smoked goods, and ready-to-eat meals.

- Medical & Pharmaceutical Companies: For sterilizing and protecting sensitive devices and components.

- Electronics Manufacturers: To shield components from moisture and dust.

Consider your production volume, product type, and budget. While the initial investment is higher than a chamber vacuum sealer, the ROI through increased efficiency, reduced waste, and higher product quality is substantial for medium to large-scale operations.

Ready to Elevate Your Packaging Line?

Thermoforming vacuum packaging isn’t just a step up; it’s a leap forward in packaging technology. It delivers the freshness, appearance, and efficiency that modern consumers and retailers demand.

Are you exploring ways to optimize your packaging process? Our experts are here to help you determine if a thermoforming vacuum packaging machine is the perfect solution for your unique needs.

Contact us today for a personalized consultation!

留下评论